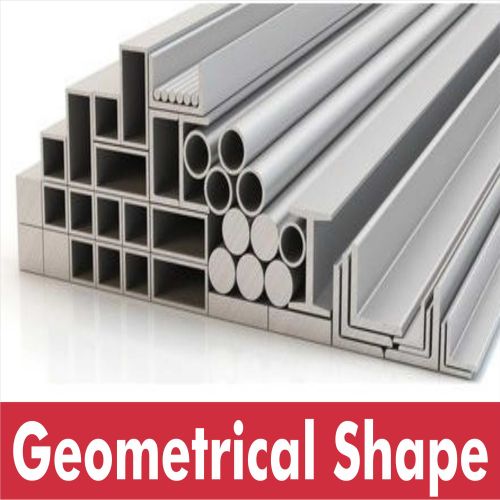

Our Range Of Aluminum Profiles

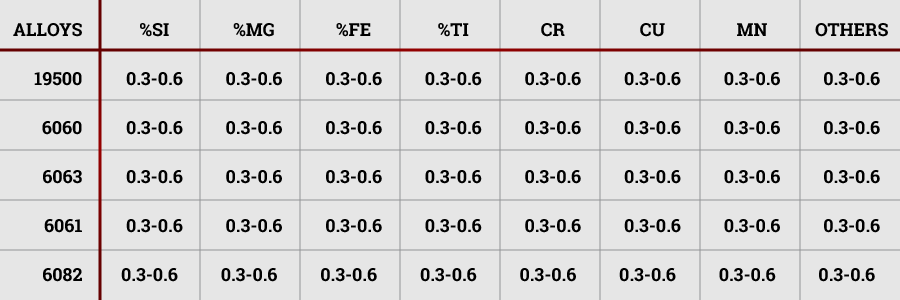

ALUMAX produce Aluminium Extrusion from Alloy AA 6060, AA 6061, AA 6063, AA6082 & AA19500 in accordance to our customer’s requirements. We offer a flexible range of products and serve a wide range of market requirements in architectural products such as doors, windows and curtain wall facade, The other products in interior & industrial products like kitchen products, form-work, truck body, air condition grills, ladders, electrical products & other similar products.

The company has the vision to provide services in Aluminium extrusion to all the fields. It has the capability for high quality Aluminium profiles on our own designs refer as standard and to customers’ specifications as well. They do the extrusion process by using a high tech hydraulic extrusion press. We can extrude hollow profiles to a maximum cylindrical dimension of 200 mm and rectangular hollow section up to 320 mm depend upon shape & 320 mm solid sections.

Aluminum is known for its peculiar light weight, high strength material properties, ease of Fabrication, flexibility in surface treatment (anodizing & powder coating), minimum maintenance, life time performance and recyclable nature.

Technical Specifications

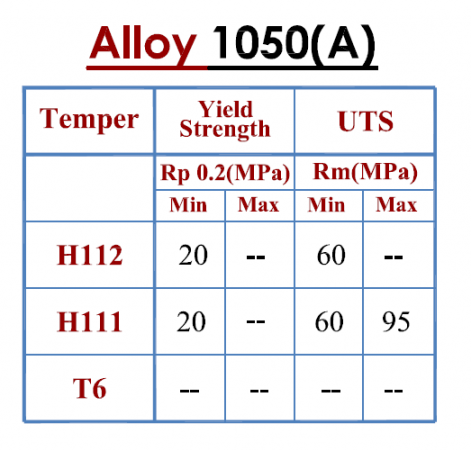

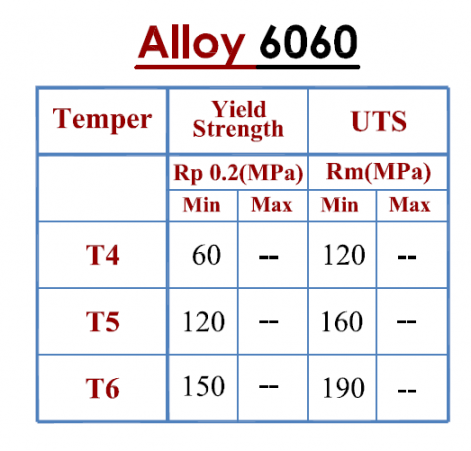

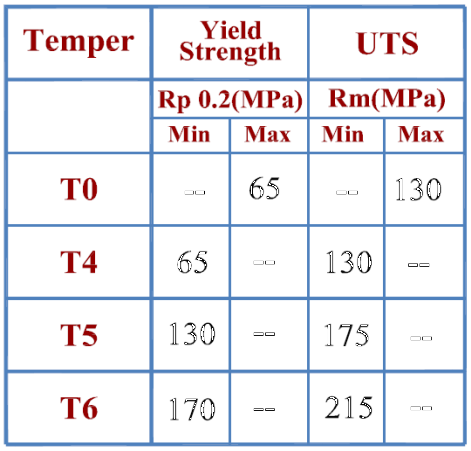

Mechanical Properties: (Reference Standard BS EN 755-2)

With an appropriate extrusion, following required parameters and heat treatment conditions,

the minimum mechanical properties shown below will be achieved as specified in the BS – EN

755 – 2.

The test for mechanical properties was followed according to BS EN 755-2 and testing sample prepared according to BS EN 755-2. The tensile test was also monitored in accordance to BS EN

10002-1.

Standard Temper Designation: (Reference Standard BS EN 515)

T-5/T-6, Solution heat treated and then artificially aged.

T-4, Naturally aged.

T-0, Annealing.

Surface Quality: (Reference Standard-BS EN-12020-1)

The extruded surface shall be free from defects, prejudicial to its suitable and proper use.

Checks are carried out surface quality at different stages of manufacturing against approved AAC standard reference sample (Both mill finish and finish treat) to ensure the significant surface of the product is a good quality.

DIMENSIONS

Tolerances on dimensions are classified into three categories

STANDARD TOLERANCES

Applicable to all extruded profile – confirming to EN 755.

SPECIAL TOLERANCES

Applied only on customer request – confirming to EN 12020-2.